Power chucks are an essential and versatile tool for machining processes, but they must be adequately maintained to work efficiently. This article examines the importance of maintenance when handling a power chuck and how to ensure a stationary power chuck or compensation chuck is adequately cared for. With proper maintenance, these tools can last longer and perform optimally. Read on to learn more about the significance of adequate supervision for power chucks and why it should be taken seriously.

Types of Power Chucks

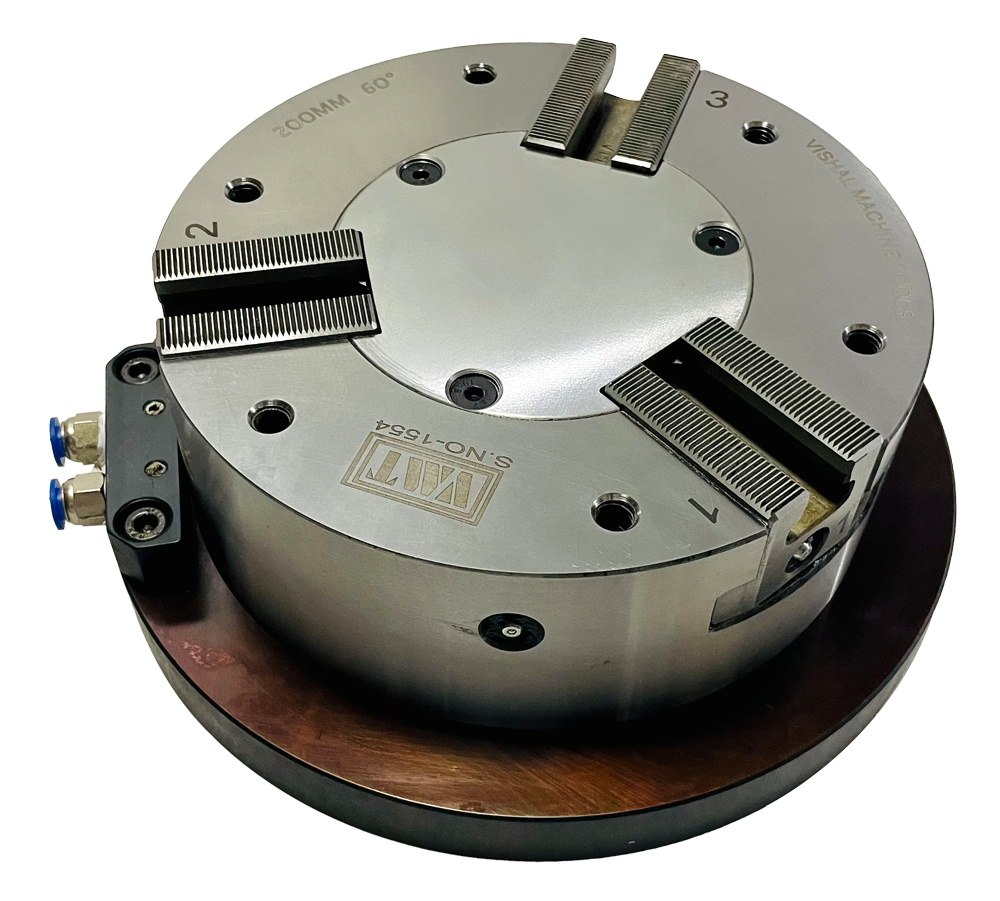

The two main categories of power chucks include mechanical and hydraulic. Mechanical power chucks use spring-loaded clamps or jaws to secure materials, while hydraulic types use liquid pressure. These two varieties are further broken down into manual, semi-automatic, and automatic styles depending on the level of control required for a particular task.

Risks of Improper Maintenance

When power chucks are not adequately cared for or misused, they can cause severe injury or even death due to the high-speed rotation of the compensation chuck. Improper maintenance can weaken key components and wear them down quickly, compromising the safety and effectiveness of your power chuck’s performance. Poor maintenance habits can also lead to premature failure of critical parts like seals and bearings, resulting in costly repairs or replacement expenses that could have been avoided with proper maintenance techniques.

Benefits of Regular Maintenance

Regular power chucks maintenance is essential for machinery’s safe and efficient operation. Not only will proper upkeep extend the lifespan of a compensation chuck, but it can also help to ensure that the machine functions optimally and reduce costly downtime due to breakdowns. Regular maintenance can also improve safety in the workplace, as worn or defective parts pose an increased risk of injury to operators.

Steps to Properly Maintain Power Chucks

Here are some steps you can take to ensure your power chucks remain in top condition:

First, it’s essential to inspect the chuck for signs of wear or damage regularly. If a component appears worn out or broken, it should be replaced immediately. It is also recommended that the chuck be lubricated periodically using appropriate grease or oil explicitly designed for use on power chucks. In addition, compensation chucks should have their gripping force regularly tested, as this can affect their reliability and accuracy over time.

Conclusion: Essential for Performance

To ensure safety and optimal performance, following the manufacturer’s instructions for regular cleaning and lubrication of the chuck components is essential. Additionally, it is recommended that all necessary replacement parts be kept in stock to replace any faulty parts before they cause further damage quickly.

Website: https://vishalmachinetools.com/